ABS Sicherheitsstandards

What do climbing harnesses and avalanche airbag systems have in common?

Climbing harnesses and avalanche airbag systems are both personal protective equipment (PPE) and are therefore subject to the PPE Regulation in the EU. PPE in categories two and three must undergo an independent type examination. The most important basis for the type examination is the standard in which the rules of technology are laid down. The most important requirements of the EN 16716 standard for avalanche airbag systems are shown in the film and summarized in the Knowledge Base article.

Functional time and temperature range

After at least 24 hours at -30 °C, the avalanche airbag system must meet the requirements for activation and inflation without external support (e.g. power supply, pressure support).

Within the temperature range specified by the manufacturer or between -30 °C and +50 °C (whichever is higher), no damage to the avalanche airbag system may occur and it must meet the requirements for deployment and inflation.

Electrically operated avalanche airbag systems must indicate when the battery reaches a low residual operating time. After reaching this state, the avalanche airbag systems must be able to be deployed for at least 6 hours.

Number of deployments

The avalanche airbag system must withstand twice the number of deployments specified by the manufacturer as the nominal number of deployments. The nominal number of deployments must be at least 20.

Pressure test

All components of the airbag system that are under pressure when fully inflated must be able to withstand the operating pressure plus 0.1 bar for at least 30 minutes without damage.

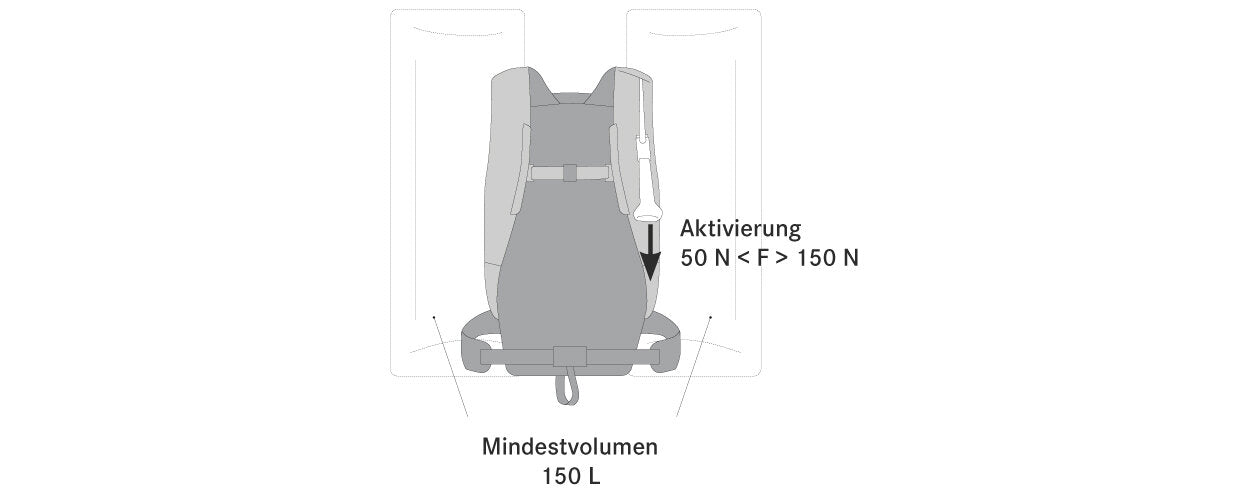

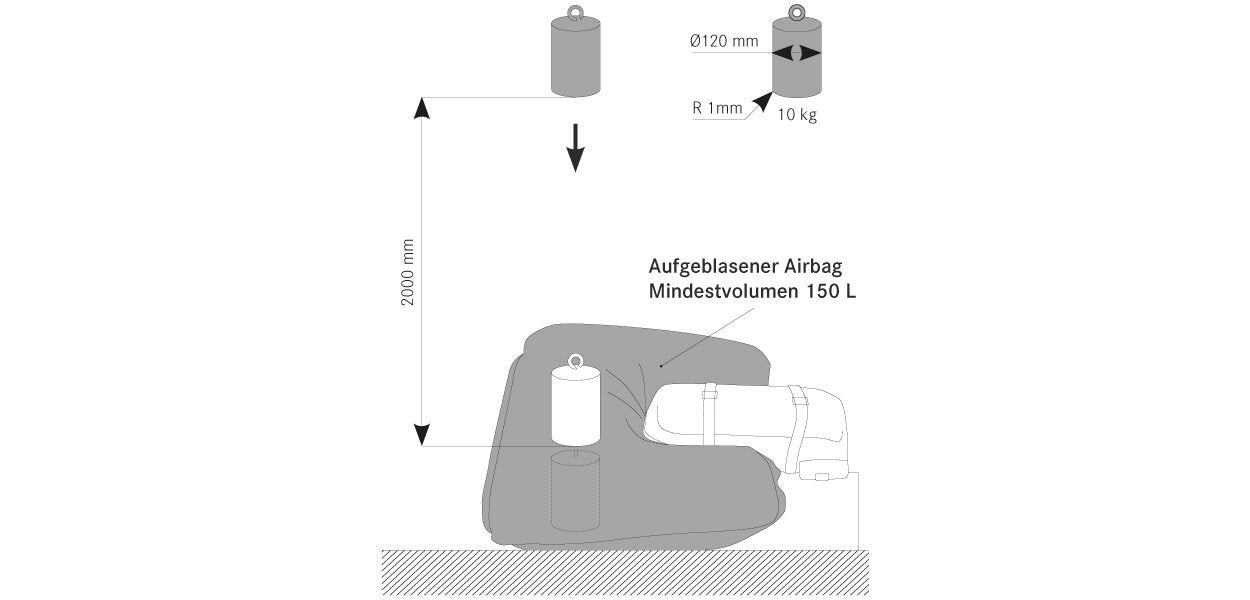

Impact test of the airbag

The fully inflated avalanche airbag system shall be placed on a hard, flat and smooth surface so that the airbag touches the surface.

An impact test shall be performed on the center of the fully inflated airbag with a cylindrical steel weight of 10 kg with a diameter of 120 mm and an edge radius of 1 mm, dropped vertically from a height of 2 m. The airbag shall survive the impact test undamaged and meet the requirement of a minimum volume of 150 l. The airbag shall not be damaged. The airbag must survive the test undamaged and meet the minimum volume requirement of 150 liters.

Testing the carrying system

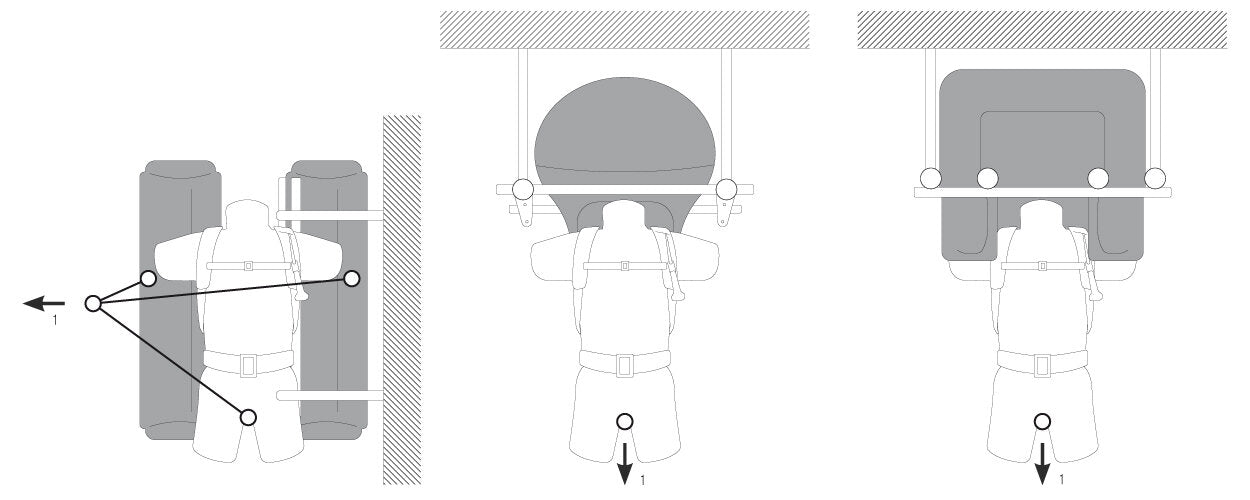

The avalanche airbag system must be put on a test torso in accordance with EN 12277 (including leg loops) in accordance with the manufacturer's instructions. The shoulder strap must be loosened against the direction of loading. A force of 3 kN is to be applied to the test torso for 1 min, whereby the fully inflated airbag is to be held as shown in Figure 2.

The test arrangement varies depending on the type of airbag:

Checking the pull-off strength

Slipping of the carrying system from the avalanche airbag system over the user's head must be prevented. If a leg loop or vest is used, it must withstand a load of 800 N for at least 1 min. The leg loop or vest must not tear and the fasteners must not move by more than 20 mm.

Alternative systems that prevent the carrying system from sliding over the user's head must be tested in the same way.

Marking

The following markings must be affixed to the product:

- Manufacturer or authorized EU representative;

- The number of this European standard;

- Type designationYear of manufactureSafety recommendations for use (e.g. folding instructions, zipper operation);

- Reference to the instructions for use

Source: EN 16716:2017. mountaineering equipment. Avalanche airbag systems. Safety requirements and test methods. The standard is currently being revised and some content and values are being updated.